U.S.S. Enterprise Cargo & Transport

Created by Commodore Wilkan Targaryen on Wed Jul 24th, 2024 @ 12:22am

Cargo

Cargo Bays

The Cargo Bay, or Cargo Hold as it was sometimes referred to, is a general-purpose storage facility aboard the Enterprise.Located in multiple locations aboard the Enterprise, Cargo Bays were either assigned to hold goods to be delivered to another location or for storing supplies for the ship's crew (also known as ship's stores). Cargo Bays in the Primary Hull were smaller than their counterparts in the Secondary Hull but featured similar equipment and technologies as one another. In an emergency the Cargo Bays could be used in a variety of ways other than for typical storage, including as triage centers, brigs, and stasis unit facilities.

Few of these Cargo Bays in the Primary Hull were equipped with Cargo Transporters; however, cargo could be transported into the bay by a Transporter Specialist operating in a Transporter Room or from one of the Cargo Bays equipped with a Cargo Transporter. Many of the Stardrive Cargo Bays were outfitted with doors that opened into space, allowing for the quick transfer of cargo and other goods aboard the Enterprise. Shuttlecraft and Workbees loaded with cargo management units could be flown into directly into these bays depending upon the situation. Anti-gravity units and Tractor Beam Generators were also available to assist personnel in moving large containers easily, while a cargo conveyor connected the forwardmost cargo bays to those aft.

|

|

|

|

Storage Compartment

Storage Compartments were a specialized facility in which various items were kept. Aboard the Starship Enterprise, Storage Compartments were often used to store materials that were unable to be replicated or were not easily obtained. Among the most common items stored aboard the Enterprise in Storage Compartments were deuterium and fresh water; however, other materials could also be maintained aside from liquids. Depending upon the nature of the items stored, Starfleet Security personnel could be assigned to continually guard the location to protect their cargo.

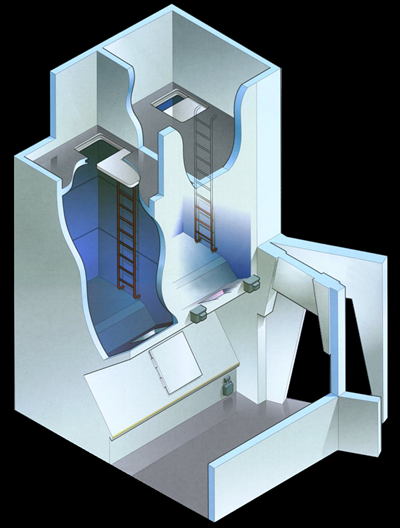

Storage Compartments were a specialized facility in which various items were kept. Aboard the Starship Enterprise, Storage Compartments were often used to store materials that were unable to be replicated or were not easily obtained. Among the most common items stored aboard the Enterprise in Storage Compartments were deuterium and fresh water; however, other materials could also be maintained aside from liquids. Depending upon the nature of the items stored, Starfleet Security personnel could be assigned to continually guard the location to protect their cargo.The typical Storage Compartment aboard the Enterprise featured a base layout with access provided either by an entry hatch at the top of the unit or from the bottom via corridor-based access. Each Storage Compartment is large enough to store a variety of goods by design, but often the storage areas are divided into sections by archways constructed along their outer passages. Each compartment has a fixed ladder that runs the entire height of one of the tankage walls, which allows the room to be easily maintained when empty, and ease of movement through these high security areas.

While most Storage Compartments are fixed locations aboard the Century Class, some compartments have been designed to be detached from the outer hull and extracted. This allows for the quick transfer of goods from the vessel to another location, such as a starbase, planet, or another vessel.

Transport

Airlock

Airlocks aboard the Starship Enterprise were points of entry to the starship which allowed ingress and egress to empty space or another vessel or station which had docked with the portal. Century Class starship airlocks were located on the port and starboard sides of the vessel but were concealed by hull plating that extended out to reveal the airlock doors when needed. The only unconcealed airlocks were located on Deck 10.

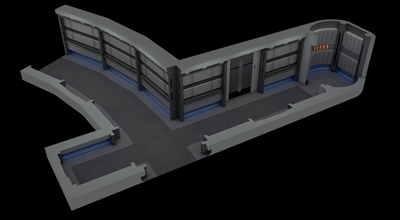

Airlocks aboard the Starship Enterprise were points of entry to the starship which allowed ingress and egress to empty space or another vessel or station which had docked with the portal. Century Class starship airlocks were located on the port and starboard sides of the vessel but were concealed by hull plating that extended out to reveal the airlock doors when needed. The only unconcealed airlocks were located on Deck 10.Airlocks aboard the Enterprise were similar in design to the corridors of the starship, but featured thick security gates used to isolate the interior of the vessel from space. The exterior airlock featured a universal fitting designed to be compatible with all known airlocks currently encountered by the Federation. The airlock could further deploy a set of long, foldable bridges that could fold out and dock with another spacecraft to extend the airlock's reach. These bridges were then sealed with force fields, allowing for rapid transfer of crew. The airlock corridors were normally dark, but extensive lighting would be activated when Enterprise was docked with a craft to enhance the safety of users of the airlock during transit. Sophisticated security sensors incorporated built-in weapon detectors that were capable of detecting military technology carried by persons boarding the Enterprise from docked starships or bases. A nearby cabinet stored environmental suits, a special form of clothing designed to be used for protection or life support in inhospitable environments, and other equipment that may be needed.

Corridor

A Corridor is a pathway located within the Starship Enterprise that connected various stations or quarters, and as lengthy hallways through which a person could access various rooms aboard the ship.

A Corridor is a pathway located within the Starship Enterprise that connected various stations or quarters, and as lengthy hallways through which a person could access various rooms aboard the ship. Corridors on board Starfleet vessels were usually of two types: radial (those which ran outward, pointing toward the outer hull) and concentric (those which lay in rings, interconnecting the radial corridors). The angled surfaces of each concealed different support structures to aid the crew in their missions, with some incorporating computer terminals. Radial corridors were angled on either side and their walls concealed a variety of supply lines and conduction systems, data networks, and power trunks. These systems were accessible by the removal of the snap-locked panels which cover them, and all were marked. The ship's concentric corridors housed personnel support systems.

Several safety and survival features were built into the walls and ceilings of Corridors, as were running lights to indicate whenever the starship was operating under alert status. In each corridor segment, an emergency survival compartment existed which provides atmosphere, food and communications for one crew member; this provision was to be used should sudden decompression of the ship interior occur due to hull damage or life support failure. For safety purposes force fields could be erected in corridors to confine intruders or isolate a section of the ship from others.

Docking Bay

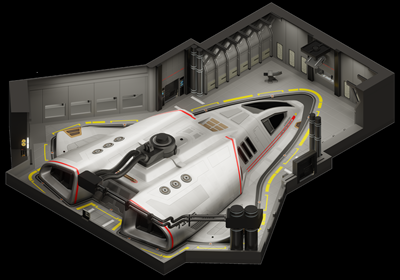

Built into the underside of the Enterprise's Stardrive Section, the Docking Bay is a specialized Shuttlebay used for the storage of the Enterprise's Captain's Yacht. Located on Deck 14, with its associated access ramp on Deck 13, the Docking Bay includes all the necessary components to ensure the safe and efficient operation of the Captain's Yacht, the Waverider II Class Galileo Galilei.

Built into the underside of the Enterprise's Stardrive Section, the Docking Bay is a specialized Shuttlebay used for the storage of the Enterprise's Captain's Yacht. Located on Deck 14, with its associated access ramp on Deck 13, the Docking Bay includes all the necessary components to ensure the safe and efficient operation of the Captain's Yacht, the Waverider II Class Galileo Galilei.While primary access to the Captain's Yacht is through a ramp directly connecting to the aft compartment of the craft, primary access to the Docking Bay is provided by doors on the port and starboard sides of Deck 14. Large observation windows built into the walls of the compartment allow people to look into the Docking Bay from the nearby Corridor. Upon entry to the Docking Bay, most were surprised by how snugly the Galileo Galilei was fitted into the room. Very little open space was available near the craft for direct observation or interaction with the vehicle, requiring Engineers to be creative during repairs due to the size. Powerful docking clamps held the vessel steady within the bay while automated fuel and power supply systems connected from Deck 13 above to help ensure that the vehicle was ready to deploy within a moment's notice. Nearby equipment lockers held needed parts and tools, as well as EVA suits should they be needed.

Launching the Captain's Yacht was nearly the same procedure as used when deploying any other vessel, despite the vehicle being docked on the underside of the primary hull. Upon launching, the Galileo Galilei quickly dropped away from its Docking Bay to help protect the Enterprise's systems. Despite this, the departure of the Waverider II Class vessel left a rather large hole open in the underside of the Enterprise. While the Galileo Galilei was away Structural Integrity Field strength in the Docking Bay was increased to compensate, and emergency forcefields employed to seal the opening until the vessel could return.

Parking Bay

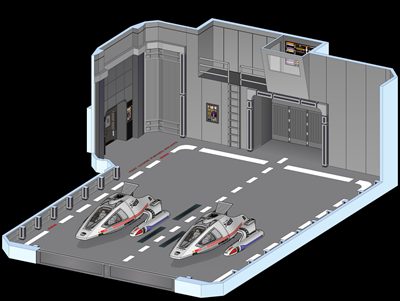

Located near to each Shuttlebay aboard the Starship Enterprise, the Parking Bay (also known as a Hangar Bay) was a specialized facility used for storing shuttlecraft and related vehicles in a safe and secure area.

Located near to each Shuttlebay aboard the Starship Enterprise, the Parking Bay (also known as a Hangar Bay) was a specialized facility used for storing shuttlecraft and related vehicles in a safe and secure area. Utilized for the construction, repair, and storage of auxiliary craft, each Parking Bay had a similar function aboard the Enterprise, but not a uniform design based upon their location aboard the vessel. Each Parking Bay was a large room that contained designated parking areas for each support craft assigned to it. Maintenance equipment could be deployed to each parking area to perform diagnostic maintenance of the shuttles as needed, but more complicated repairs could be moved to a Shuttle Maintenance Bay. Connective hoses would be used to transfer fuel from nearby tanks to the support craft during fueling. When a shuttle was needed for a mission, specialized tractor beams would move the shuttle from its parking area to the centralized elevator or pressure door to move the craft into the Shuttlebay.

Each Parking Bay was equipped with a vehicle replicator. A specialized industrial replicator, the vehicle replicator was a large-scale replicator that was able to quickly create mechanical parts or any means of transportation, including shuttlecraft, if needed. The vehicle replicator worked by stringing together individual replicated components at a time, providing audio updates as construction proceeded until completion.

Shuttlebay 1 and Shuttlebay 2

Located on Decks 7 and 8 in the aft section of the Primary Hull, Shuttlebays 1 and 2 are among the largest single locations aboard the Starship Enterprise. Part of the larger Shuttlebay Complex, these Shuttlebays are direct remnants of earlier design briefs calling for the Century Class to become a mobile outpost and carrier starship instead of a dedicated Explorer. Due to the risk of hazards impacting the Enterprise's mission, a shuttle could successfully be launched or land aboard the vessel in less than ten seconds in an emergency.

Located on Decks 7 and 8 in the aft section of the Primary Hull, Shuttlebays 1 and 2 are among the largest single locations aboard the Starship Enterprise. Part of the larger Shuttlebay Complex, these Shuttlebays are direct remnants of earlier design briefs calling for the Century Class to become a mobile outpost and carrier starship instead of a dedicated Explorer. Due to the risk of hazards impacting the Enterprise's mission, a shuttle could successfully be launched or land aboard the vessel in less than ten seconds in an emergency. Primary personnel access to either Shuttlebay 1 or 2 is provided by pressure doors located on Deck 8 on the main level of the Shuttlebay. Primary entry to the Shuttlebay is through the Enterprise's Spaceflight Terminal, a large sitting area directly adjacent to the main component of the Shuttlebay. Dedicated Starfleet Security Officers are assigned to the Spaceflight Terminal to conduct customs and security checks on any new arrivals to protect the Enterprise from potential threat. A large model of the Enterprise is on display within each Spaceflight Terminal and computer terminals can be used to become better acquainted with the starship. Lockers were fitted within the Spaceflight Terminal for storage.

Brightly lit, Shuttlebay 1 and 2 was designed to maximize functional space and to keep deck space uncluttered, with the main floor of the room providing parking for craft visiting the Enterprise. Landing lights and floor markings aided pilots in navigating craft into the Shuttlebay to help avoid incident; however, a combination of computer assisted guidance and tractor beams were more frequently used to safely position a craft aboard the Enterprise. An exterior pressure door served as the outermost wall of the Shuttlebay and spanned two decks. During normal operations specialized forcefield technology was used to prevent the decompression of the Shuttlebay while the exterior door was open, but advanced safety systems were available to protect personnel in the event that the containment field failed. Twin large elevators were positioned in the far section of the Shuttlebay and were used to either lower shuttles into the Parking Bay below, or to serve as Landing Pads for incoming vehicles too large to use the outer door. Large displays on the back wall of the Shuttlebay provided details on arriving and departing vessels. Twin garage doors below these displays allowed access to Refueling & Maintenance Storage Bays.

The upper level of the Shuttlebay Complex included the dedicated Control Room for the Shuttlebay as well as a small lounge for visitor usage. The lounge featured large couches, tables, and a Food Replicator that could be used to provide meals and other refreshments while someone was waiting to depart. Many people enjoyed visiting the lounge in the Shuttlebay just to observe the impressive operations within the Shuttlebay below, and to watch guests as they arrived aboard.

Shuttlebay 3

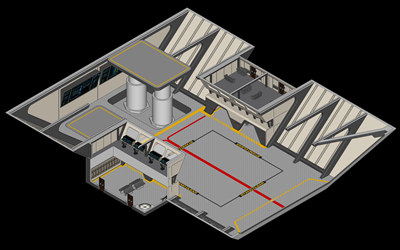

Shuttlebay 3 is one of three Shuttlebay facilities aboard the Century Class Starship Enterprise. Comprised of multiple levels accessible from Deck 14, Shuttlebay 3 was enormous and had several design and systems upgrades to make operations safer for all personnel and guests to the vessel.

Shuttlebay 3 is one of three Shuttlebay facilities aboard the Century Class Starship Enterprise. Comprised of multiple levels accessible from Deck 14, Shuttlebay 3 was enormous and had several design and systems upgrades to make operations safer for all personnel and guests to the vessel.Brightly lit to enhance the safety of its operations, Shuttlebay 3 was externally accessed by a large rolltop door which rose into the vessel's hull to allow support vessels to enter and exit the spacecraft. Specialized forcefield technology prevented decompression of the Shuttlebay when the space doors were opened but allowed shuttlecraft or other vehicles egress. In an emergency the forcefield could be deactivated to cause an emergency decompression strong enough to move the Enterprise herself.

Support vessels ready for deployment were transferred into Shuttlebay 3 via tractor beam if they were in the rear parking bay or via a vehicle elevator; however, vehicles could also be parked along the side bulkheads of the Shuttlebay if needed. A Control Room was installed on the upper level that was used by personnel to oversee shuttlecraft operations. Temporary storage space was located on each side of the Shuttlebay to allow the bay floor to remain unobstructed, while access to the corridor was provided by a single door located on the rear wall. Landing lights were prominently positioned to provide guidance during landings, and written warnings were displayed across the bay floor to assist pilots on manual approach. Despite this, most landings were automated using a combination of computer assisted guidance and tractor beam. Should a shuttle escape all other protections, emergency nets were concealed within the floor that could be deployed to try to minimize damage if the shuttle had been disabled.

Shuttlebay Control Room

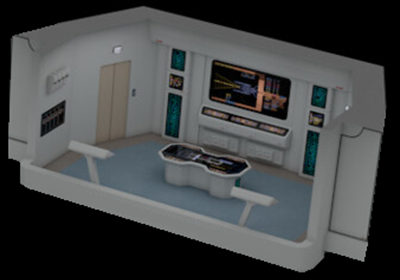

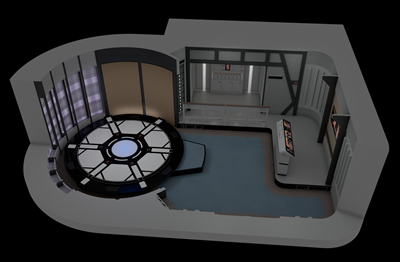

Located on the upper level of each Shuttlebay aboard the Starship Enterprise, the Shuttlebay Control Room was responsible for the operation of each Shuttlebay aboard the ship. Surprisingly small for their level of importance in the operations of the Enterprise's support craft, each Shuttlebay Control Room has been designed with efficiency and ease of access in mind.

Located on the upper level of each Shuttlebay aboard the Starship Enterprise, the Shuttlebay Control Room was responsible for the operation of each Shuttlebay aboard the ship. Surprisingly small for their level of importance in the operations of the Enterprise's support craft, each Shuttlebay Control Room has been designed with efficiency and ease of access in mind.The central feature of the Shuttlebay Control Room is the Situation Table, which dominates the center of each Control Room. From this location a member of the Shuttlebay Deck Crew can access any detail needed about the Enterprise's Support Craft, including assigned personnel, flight plan, mission profile, and vessel status. Constantly updated with information related to the Enterprise's support craft, a Technician can control the entire complement of auxiliary vessels from this one terminal in an emergency, even if they are located in another Shuttlebay.

Twin freestanding workstations are positioned next to a large transparent aluminum window that overlooks the entire Shuttlebay. Technicians assigned here have an unobstructed view of all operations in the Shuttlebay from this location. The opposite wall is outfitted with a large display terminal and keyboard that maintains details about optimal flight operations. Auxiliary monitors supplement the situation table, offering a list of all arrivals and departures.

Shuttlecraft Maintenance Bay

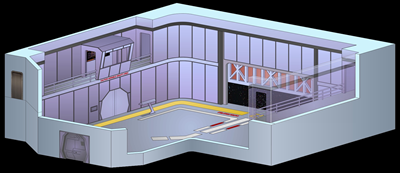

Shuttlecraft Maintenance Bays are specialized chambers constructed adjacent to the Hangar Bays and Shuttlebays of the Starship Enterprise that are used for the repair of small craft. Staffed by trained Engineers, access to each Shuttlecraft Maintenance Bay is restricted due to the equipment stored there.

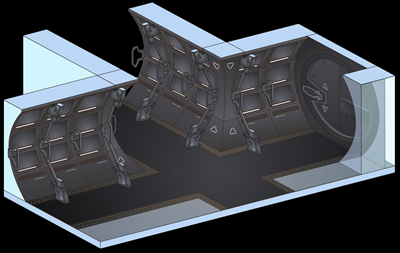

Shuttlecraft Maintenance Bays are specialized chambers constructed adjacent to the Hangar Bays and Shuttlebays of the Starship Enterprise that are used for the repair of small craft. Staffed by trained Engineers, access to each Shuttlecraft Maintenance Bay is restricted due to the equipment stored there.Each Shuttlecraft Maintenance Bay incorporates the necessary technologies to repair small craft experiencing technical or other maintenance issues. Personnel enter the Maintenance Bay via corridor access doors while shuttles are transferred into the bay by garage doors built into the bulkhead of the room. Shelving units and other storage cabinets maintain replacement parts and tools that can be used by technicians in the repair of vehicles brought there for servicing, while larger components that are unable to be replicated are also available in storage within the bay. Computer terminals tied to sophisticated diagnostic sensors allow for enhanced investigation of technical challenges experienced by support vessels.

Transporter Room

Aboard Century Class vessels Transporter Rooms are used to move lifeforms and small inanimate objects to and from the ship. Located throughout the Enterprise, Transporter Rooms feature all of the key components that are needed for transport with additional support equipment located nearby.

Aboard Century Class vessels Transporter Rooms are used to move lifeforms and small inanimate objects to and from the ship. Located throughout the Enterprise, Transporter Rooms feature all of the key components that are needed for transport with additional support equipment located nearby.Overseen by a Transporter Specialist, each Transporter Room includes a transporter chamber with a corresponding transporter platform. The transporter platform is fitted with six emitter pads, which were numbered clockwise beginning with the right front, that were used by the person being transported. In the event that cargo or equipment needed transported, the large section in the middle of the transporter platform would be used to transport such materials to and from the ship.

Opposite the transporter chamber, the Transporter Specialist worked from a large display console located on an elevated platform. A large monitoring console, attached to the bulkhead behind the technician, provided an overview of the status of the transporter system and allowed for fine control over the components if necessary. During more complicated transports a second technician could work in conjunction with the specialist from this wall console, such as if an emergency occurred where someone needed directly transported to sickbay or a large scale evacuation was required.

Entry to the Transporter Room was provided by a single door, which led to a staging area where an away team could prepare for their assignment. Attached to the upper platform containing the operator's console was a small alcove that featured an equipment bay and a storage locker that held equipment and supplies an away team could check out for their assignment. A circuitry bay adjacent to the storage compartment maintained the primary equipment that allowed the Transporter to function, including the Biofilters, Pattern Buffer, and Primary Computer System. Technicians could use this area to quickly access the system hardware to easily make modifications or repairs. For the safety of all parties, this area was separated with handrails from the pad in order to prevent quick access to potential hostiles.

Secondary Transporter Room

Compact and functional in design, Secondary Transporter Rooms are similar in capability to other Transporter Rooms elsewhere on the ship, but with some limitations. Due to their compact nature, the transporter pads in these rooms were smaller than those of the Primary Transporter Rooms on other decks and could only accommodate three people at a time but maintained a similar design. Despite this, these transporter pads were fast and efficient in their responsibilities, easily transporting users to and from the ship.

Compact and functional in design, Secondary Transporter Rooms are similar in capability to other Transporter Rooms elsewhere on the ship, but with some limitations. Due to their compact nature, the transporter pads in these rooms were smaller than those of the Primary Transporter Rooms on other decks and could only accommodate three people at a time but maintained a similar design. Despite this, these transporter pads were fast and efficient in their responsibilities, easily transporting users to and from the ship. Directly across from the Transporter Chamber was a small alcove holding the operator's console for the Transporter system. Located on a slightly raised platform, the control interface was streamlined in the Secondary Transporter Room, but was supplemented by a larger panel located on the bulkhead behind the operator. Beside the centralized staging area, an equipment bay housing the primary transporter hardware was easily accessible to allow for quick maintenance, especially in an emergency. A nearby cabinet located near the circuitry bays stores equipment for away teams as well.

Turbolift

The Turbolift is a rapid transport unit aboard the Starship Enterprise. Capable of traveling both vertically and horizontally through a system of turboshafts between key sections of the ship, Turbolift allow for quick and efficient travel through the ship. Two Turbolift types are available aboard the Enterprise. Standard Turbolifts are general use lifts that can go to any Deck aboard the vessel while Express Turbolifts are only designed to go to specific locations aboard the starship.

The Turbolift is a rapid transport unit aboard the Starship Enterprise. Capable of traveling both vertically and horizontally through a system of turboshafts between key sections of the ship, Turbolift allow for quick and efficient travel through the ship. Two Turbolift types are available aboard the Enterprise. Standard Turbolifts are general use lifts that can go to any Deck aboard the vessel while Express Turbolifts are only designed to go to specific locations aboard the starship. Cylindrical in shape, the Turbolifts aboard the Enterprise are smaller than their predecessors yet can still comfortably transport crew and visitors throughout the ship. Aboard the Enterprise, the Turbolift operates by voice command operation, allowing passengers to use voice commands to direct the Turbolift to a destination. Upon receipt of the voice command, the destination queried the network allowing for the ships computers to determine the optimal route to the destination - incorporation the presence of other Turbolifts already in operation into the calculation. The auditory receivers also automatically scanned for voiceprint authentication, allowing access to restricted areas for authorized personnel.

Once in motion the Turbolift provided safe and quick travel, with motion dampening systems preventing most personnel from identifying that the lift is in operation. Light from the turboshaft frequently shone through the grid, serving as one of the few methods of identifying travel. A display on the back wall of the lift provided details on travel through the ship and allowed for the manual entry of a destination and further featured a built-in companel to allow communication with other sections of the ship without the need for a communicator.

Disclaimer

The Enterprise's Cargo & Transport Section utilizes several designs from several talented artists. These include:

- Bobye (Airlock, Cargo Bay Type 2, Cargo Bay Type 3, Cargo Bay Type 4, Parking Bay, Shuttle Bay 3)

- Falke (Cargo Bay Type 1, Docking Bay, Shuttle Bay 1 and Shuttlebay 2, and Shuttlecraft Maintenance Bay)

- Tadeo D'oria (Corridor, Shuttlebay Control Room, Transporter Room, and Secondary Transporter Room)

The Enterprise's Storage Compartment and Turbolift are based upon locations created for various Star Trek television programs designed by Paramount Pictures. No infringement intended. Images retrieved from Ex Astris Scientia.

Categories: No categories found