U.S.S. Enterprise Engineering Section

Created by Commodore Wilkan Targaryen on Mon Apr 22nd, 2024 @ 1:40am

Engineering

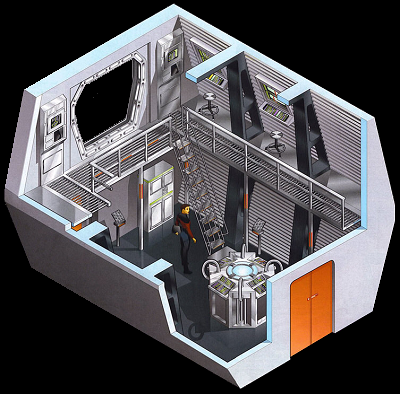

Impulse Engineering

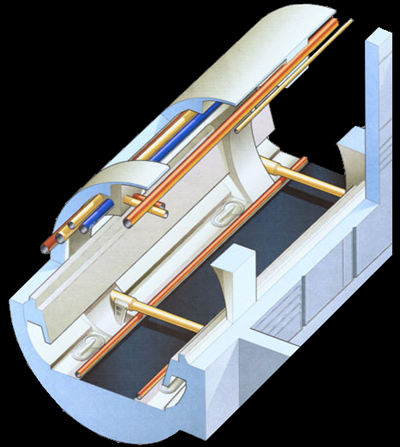

Located within each Impulse Engine Assembly, Impulse Engineering houses and controls the Impulse Engines aboard the Enterprise. Comprised of two levels, The Impulse Engines consist of four fusion reactors producing highly energized plasma, a driver coil assembly, and a vectored thrust nozzle to direct the plasma exhaust. Energy not utilized for propulsion can be diverted through the Electro Plasma System via EPS conduits, so as to supply power to other systems.

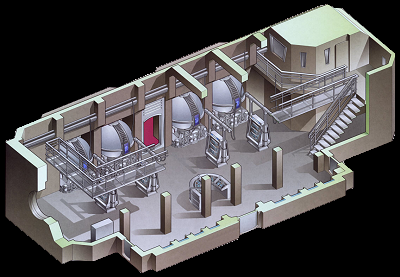

Located within each Impulse Engine Assembly, Impulse Engineering houses and controls the Impulse Engines aboard the Enterprise. Comprised of two levels, The Impulse Engines consist of four fusion reactors producing highly energized plasma, a driver coil assembly, and a vectored thrust nozzle to direct the plasma exhaust. Energy not utilized for propulsion can be diverted through the Electro Plasma System via EPS conduits, so as to supply power to other systems. Primary entry to the Impulse Deck is through the upper level next to the enclosed control room. Suspended catwalks intersect the area above the main deck and allow users an unobstructed view of the engine assembly. While compact, the catwalks feature multiple workstations built into the safety railing that are used to monitor the Impulse Grid and its efficiency.

The dominant feature of the main floor of the Impulse Deck are the four spherical Fusion Reactors built into the aft bulkhead. Touch sensitive controls are built into each reactor allowing a user to manipulate the reactor directly while freestanding double-sided control panels monitor the overall status of the fusion reactors. A doorway between Reactors 2 and 3 allow engineers access to the remainder of the Impulse Engine Assembly. Parallel to this doorway on the opposite side of the room, a Master Control Console - used by the Duty Engineer - oversees all operations of the Impulse Engine Assembly.

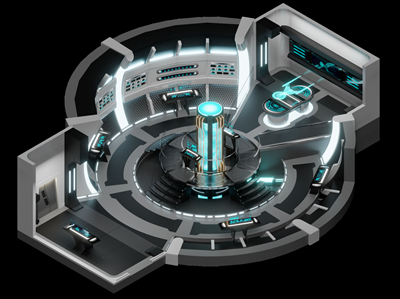

Main Engineering

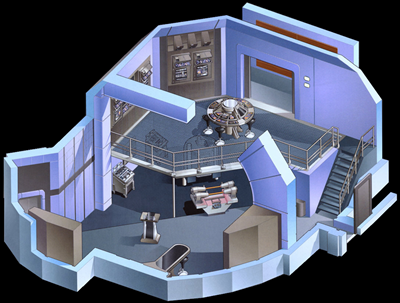

Located inside the Stardrive Section on Deck 13, Main Engineering (also known as Warp Engineering) is the primary engine room aboard the Starship Enterprise and is constantly manned by dedicated engineers. Responsible for the operation of the Enterprise's energy distribution and propulsion systems, Main Engineering is t-shaped room that shares a similar design layout to the Engineering spaces of the Galaxy Class Explorer of the 24th Century albeit with all work areas located on a single level and featuring additional security precautions over its predecessor design. Main Engineering has been specifically designed to allow easy access to the component parts of the Enterprise's Coaxial Warp Drive, allowing for improved maintenance and repair action. Safety is a priority aboard Starfleet vessels and Main Engineering is no exception to this rule. In an emergency situation the Engine Room could be isolated from the rest of the ship through a combination of emergency bulkheads and containment forcefields in an effort to protect the crew from an out-of-control matter/antimatter reaction or other threat to their safety.

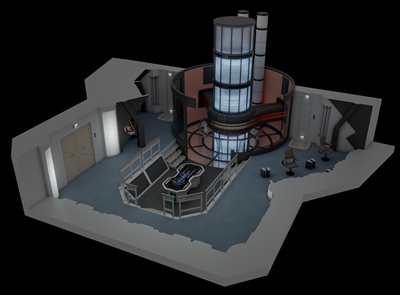

Located inside the Stardrive Section on Deck 13, Main Engineering (also known as Warp Engineering) is the primary engine room aboard the Starship Enterprise and is constantly manned by dedicated engineers. Responsible for the operation of the Enterprise's energy distribution and propulsion systems, Main Engineering is t-shaped room that shares a similar design layout to the Engineering spaces of the Galaxy Class Explorer of the 24th Century albeit with all work areas located on a single level and featuring additional security precautions over its predecessor design. Main Engineering has been specifically designed to allow easy access to the component parts of the Enterprise's Coaxial Warp Drive, allowing for improved maintenance and repair action. Safety is a priority aboard Starfleet vessels and Main Engineering is no exception to this rule. In an emergency situation the Engine Room could be isolated from the rest of the ship through a combination of emergency bulkheads and containment forcefields in an effort to protect the crew from an out-of-control matter/antimatter reaction or other threat to their safety.

Primary access to Warp Engineering was provided through a small anteroom adjacent to the Matter/Antimatter Reactor Core Chamber. Featuring doorways located on the port and starboard bulkheads, the anteroom is accessed via corridor with a nearby Turbolift lobby allowing quick access to other parts of the ship. The primary feature of the anteroom is the pit, which features the Master Systems Display table. This workstation, which seats two engineers, is outfitted with two octagonal-shaped terminals that could be dual operated and features schematic displays that provide updates on all systems aboard the Enterprise. The Master Systems Table is supplemented by the Master Systems Display. Similar to the console located on the Main Bridge, the Master Systems Display features a cutaway diagram of the Enterprise that would highlight any malfunctions detected by the Enterprise's diagnostic systems. Because of its maintenance orientation, often the deployment of Damage Control Teams or other maintenance personnel would be directed from this console. The bulkhead containing the Master Systems Display also incorporated circuit junctions, EPS regulators, and Engineering's primary Positronic control chips.

Primary access to Warp Engineering was provided through a small anteroom adjacent to the Matter/Antimatter Reactor Core Chamber. Featuring doorways located on the port and starboard bulkheads, the anteroom is accessed via corridor with a nearby Turbolift lobby allowing quick access to other parts of the ship. The primary feature of the anteroom is the pit, which features the Master Systems Display table. This workstation, which seats two engineers, is outfitted with two octagonal-shaped terminals that could be dual operated and features schematic displays that provide updates on all systems aboard the Enterprise. The Master Systems Table is supplemented by the Master Systems Display. Similar to the console located on the Main Bridge, the Master Systems Display features a cutaway diagram of the Enterprise that would highlight any malfunctions detected by the Enterprise's diagnostic systems. Because of its maintenance orientation, often the deployment of Damage Control Teams or other maintenance personnel would be directed from this console. The bulkhead containing the Master Systems Display also incorporated circuit junctions, EPS regulators, and Engineering's primary Positronic control chips.

Lining the Matter/Antimatter Reactor Core Chamber the Observation Gallery allowed the Engineers to visually monitor the Warp Core. Crescent shaped, Observation maintains dedicated workstations that manage a variety of systems aboard the Enterprise and provides at-a-glance updates to the duty engineers on the status of the propulsion systems. The wall closest to the Warp Core was made of transparent aluminum to allow the engineers the ability to directly monitor the Warp Core visually and offered a holographic overlay that could be used to control the Warp Core's functions or get updates on the status of the engine core. The Duty Engineer's workstation was in the port Observation Gallery directly opposite the observation window and incorporated dedicated display terminals that provided details on the status of all systems aboard the Enterprise. From this workstation a user could, effectively, control the entire starship in an emergency as it had priority linkages to all shipboard systems. The Propulsion Systems monitor console was located next to the Duty Engineer's console. Located on the opposite side of the Engine Room, the starboard gallery mirrored the Duty Engineer's area and contained two workstations, including an Emergency Override Console. Open ladderways within both galleries allowed access to the Jefferies Tube Network.

Lining the Matter/Antimatter Reactor Core Chamber the Observation Gallery allowed the Engineers to visually monitor the Warp Core. Crescent shaped, Observation maintains dedicated workstations that manage a variety of systems aboard the Enterprise and provides at-a-glance updates to the duty engineers on the status of the propulsion systems. The wall closest to the Warp Core was made of transparent aluminum to allow the engineers the ability to directly monitor the Warp Core visually and offered a holographic overlay that could be used to control the Warp Core's functions or get updates on the status of the engine core. The Duty Engineer's workstation was in the port Observation Gallery directly opposite the observation window and incorporated dedicated display terminals that provided details on the status of all systems aboard the Enterprise. From this workstation a user could, effectively, control the entire starship in an emergency as it had priority linkages to all shipboard systems. The Propulsion Systems monitor console was located next to the Duty Engineer's console. Located on the opposite side of the Engine Room, the starboard gallery mirrored the Duty Engineer's area and contained two workstations, including an Emergency Override Console. Open ladderways within both galleries allowed access to the Jefferies Tube Network.

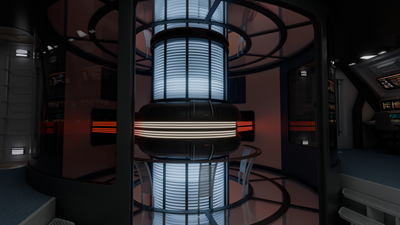

The largest section within Warp Engineering was the Matter/Antimatter Reaction Chamber compartment. Circular in shape, the Warp Core ran through the center of the room and was its primary feature. The Warp Core created the plasma that powered the Enterprise and generated the Warp Field that allowed it to travel through space. The Matter/Antimatter Reaction Chamber was located in the center of the Warp Core and was directly responsible for containing and then redirecting energy created by the Matter/Antimatter reaction. The chamber itself housed the Dilithium Crystal Articulation Frame, which was accessed through reinforced panels located on the top and bottom of the chamber giving technicians the ability to adjust or replace the critical Dilithium Crystals that manage the reaction. The plasma streams were channeled through Power Transfer Conduits that connected to the Warp Nacelles, dividing the room into three sections. Twin vertical deuterium control conduits ran behind the Warp Core. Wall mounted displays provided detailed information to users on the status of the Enterprise's Core and the Matter/Antimatter reaction. Should the internal sensors detect a potential malfunction that threatens the health and safety of the Enterprise's crew isolation doors will engage to separate the Matter/Antimatter Reaction Chamber from the rest of the Engine Room. Should the system fail to engage automatically, the Engineers may manually deploy the isolation doors from keypads directly next to the chamber.

The largest section within Warp Engineering was the Matter/Antimatter Reaction Chamber compartment. Circular in shape, the Warp Core ran through the center of the room and was its primary feature. The Warp Core created the plasma that powered the Enterprise and generated the Warp Field that allowed it to travel through space. The Matter/Antimatter Reaction Chamber was located in the center of the Warp Core and was directly responsible for containing and then redirecting energy created by the Matter/Antimatter reaction. The chamber itself housed the Dilithium Crystal Articulation Frame, which was accessed through reinforced panels located on the top and bottom of the chamber giving technicians the ability to adjust or replace the critical Dilithium Crystals that manage the reaction. The plasma streams were channeled through Power Transfer Conduits that connected to the Warp Nacelles, dividing the room into three sections. Twin vertical deuterium control conduits ran behind the Warp Core. Wall mounted displays provided detailed information to users on the status of the Enterprise's Core and the Matter/Antimatter reaction. Should the internal sensors detect a potential malfunction that threatens the health and safety of the Enterprise's crew isolation doors will engage to separate the Matter/Antimatter Reaction Chamber from the rest of the Engine Room. Should the system fail to engage automatically, the Engineers may manually deploy the isolation doors from keypads directly next to the chamber.

Slipstream Engineering

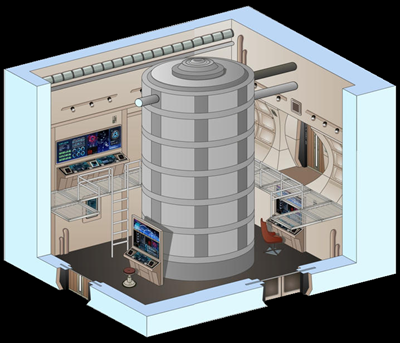

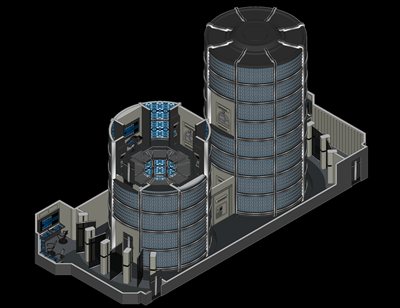

Located in the Chevron Section of the Starship Enterprise, Slipstream Engineering is an energy production facility and faster than light propulsion source aboard the vessel. Slipstream Engineering has been designed to allow easy access to the component parts of the Enterprise's Quantum Slipstream Drive and is constantly manned by dedicated engineers, who can assume control over the functions of Main Engineering in an emergency situation. Most personnel are surprised to find Slipstream Engineering to be 'busier' than Main Engineering, despite the Enterprise's Coaxial Drive being located within the Stardrive Section's Engine Room.

Located in the Chevron Section of the Starship Enterprise, Slipstream Engineering is an energy production facility and faster than light propulsion source aboard the vessel. Slipstream Engineering has been designed to allow easy access to the component parts of the Enterprise's Quantum Slipstream Drive and is constantly manned by dedicated engineers, who can assume control over the functions of Main Engineering in an emergency situation. Most personnel are surprised to find Slipstream Engineering to be 'busier' than Main Engineering, despite the Enterprise's Coaxial Drive being located within the Stardrive Section's Engine Room.When compared to its contemporaries in Starfleet, Slipstream Engineering is largely nondescript and features only a few workstations for personnel. Accessed from Deck 10, Slipstream Engineering is divided into two sections including an anteroom and the Matter/Antimatter Reaction Chamber compartment. Surprisingly narrow, the anteroom features only a single wall facing computer terminal and is primarily filled with storage compartments for various Engineering tools and other supplies. Benamite Crystals, the power source for the Quantum Slipstream Burst Drive, are stored within this section as well, keeping this essential component close to the Drive.

The Matter/Antimatter Reaction Chamber room is a spacious, well illuminated room with curved walls that has support pillars running along its walls at symmetric points. Floor space on the lower level is kept to a minimum due to the relatively low number of personnel needed to successfully control the Slipstream Drive, who work at a series of four freestanding, bulkhead facing workstations that line the dome shaped complex. The operational focus of Slipstream Engineering is the Quantum Slipstream Burst Drive Core, which is accessed via a raised circular framework located in the center of the Engine Room. Consisting of heavy-duty grille plating and supported by duranium buttresses, accesses to the Drive Core is provided by three stairways that lead up to this dais. A protective metal railing runs the entirety of the platform to provide additional protection for workers. The Master Systems Display table and a supplemental wall based Master Systems Display workstation are located behind the Core within this upper level work area.

The Matter/Antimatter Reaction Chamber room is a spacious, well illuminated room with curved walls that has support pillars running along its walls at symmetric points. Floor space on the lower level is kept to a minimum due to the relatively low number of personnel needed to successfully control the Slipstream Drive, who work at a series of four freestanding, bulkhead facing workstations that line the dome shaped complex. The operational focus of Slipstream Engineering is the Quantum Slipstream Burst Drive Core, which is accessed via a raised circular framework located in the center of the Engine Room. Consisting of heavy-duty grille plating and supported by duranium buttresses, accesses to the Drive Core is provided by three stairways that lead up to this dais. A protective metal railing runs the entirety of the platform to provide additional protection for workers. The Master Systems Display table and a supplemental wall based Master Systems Display workstation are located behind the Core within this upper level work area.

The Quantum Slipstream Burst Drive itself is unlike most propulsion systems in that it is a built from a modified Type 9 Warp Core. The Matter/Antimatter Reaction Chamber for the modified core was located between decks, with the Power Transfer Conduits located within the deck plate itself. In normal operation the Warp Plasma generated was distributed to the vessel's Warp Nacelles; however, when operating in separated flight mode, energy was distributed to the Warp Sustainer Engines built into the underside of the vessel's hull. When use of the Slipstream Burst Drive was needed, the specialized energies would be routed to the Auxiliary Deflector Dish at the front of the Primary Hull for transit.

Warp Nacelle Control Room

Located within each Warp Nacelle, the Warp Nacelle Control Room houses maintenance and monitoring systems for each nacelle assembly aboard the Enterprise.

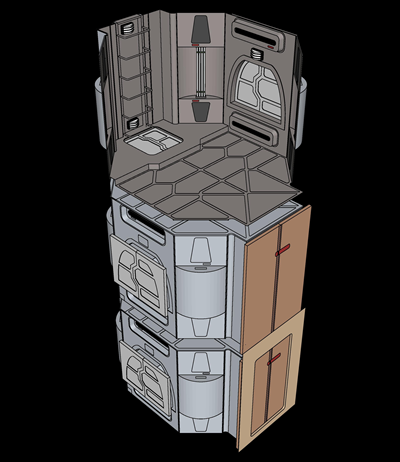

Located within each Warp Nacelle, the Warp Nacelle Control Room houses maintenance and monitoring systems for each nacelle assembly aboard the Enterprise.A small, two level compound aboard the Century Class starship the control room was located at the rear of the nacelle, near the plasma injectors, and provided engineers access to the entirety of the Warp Nacelle structure. Unlike its predecessors, the internal components of the Warp Nacelle are accessible aboard the Enterprise via service lift built into the Nacelle pylon. The lift opens upon the lower level of the control room and incorporates a large, octagonal workstation that allows direct administration of the components of the assigned nacelle. The second level, accessible by a metal staircase, provided access to the interior of the nacelle itself and was protected by a large isolation door that could be opened to access the nacelles through a large catwalk that served as a service corridor when the nacelles were powered down. When active, a one-way forcefield would engage to protect the occupants of the control room from the release of drive plasma; however, even with this protection, the doors could only remain open for ninety seconds to prevent force field degradation.

Engineering Support

Chief Engineer's Office

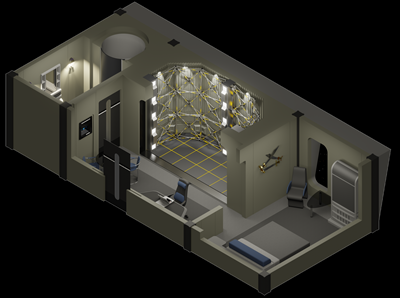

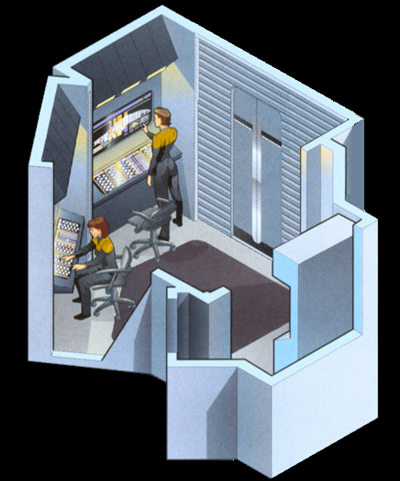

Located near Warp Engineering on Deck 13, the Chief Engineer's Office allows the Chief Engineer to work on personal projects or meet with others in privacy.

Located near Warp Engineering on Deck 13, the Chief Engineer's Office allows the Chief Engineer to work on personal projects or meet with others in privacy.The Chief Engineer's Office is smaller than the offices of other Senior Staff members aboard the Enterprise, but it is no less critical to the operations of its department head. Consisting of three compartments, the central chamber of the Chief Engineer's Office had a large workstation for the Engineer and a small conference table that could be used for meetings. Above the Chief Engineer's desk was a wall mounted workstation that repeated information from the Master Situation Display in Engineering. Directly behind the office area was a large hologrid taht allowed the Chief Engineer to explore solutions in a controlled environment, limiting the potential danger.

Inspired by the inclusion of a bedroom compartment within the Captain's Ready Room on the Enterprise, the Chief Engineer's Office has been similarly equipped. A full-sized bed is located centrally in the chamber with a small window directly parallel. A wardrobe is available to store the Chief Engineer's uniforms, and a small sitting area allows a place for the Chief Engineer to unwind. While the Engineer has a dedicated suite of rooms elsewhere on the ship, often the Chief eschews this option in favor of sleeping in the office. A private restroom is in the opposite chamber.

Engineering Laboratory

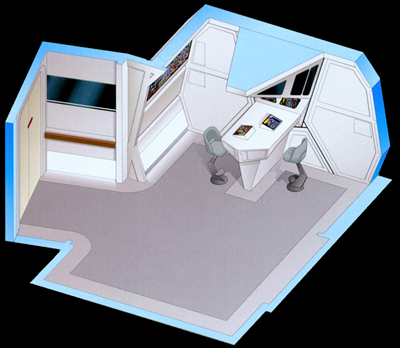

The Engineering Laboratory is a specialized scientific research facility used by the Engineering staff of the Starship Enterprise.

The Engineering Laboratory is a specialized scientific research facility used by the Engineering staff of the Starship Enterprise. Located adjacent to the Engine Rooms of the starship, each Engineering Lab is designed with efficiency as a primary concern. The center of the laboratory is dominated by an Engineering Analysis Table, a large workstation that incorporates multiple specialized sensors that are used in research projects. A large display panel is attached to the table to allow for review of findings. Additional consoles and displays are located throughout the lab that allow personnel to work on more than one project concurrently with other assignments. A curved, wall-mounted secondary interface console allows additional research space for personnel when the analysis table is unavailable or inappropriate.

An isolation room has been fitted adjacent to the secondary interface to allow personnel to investigate samples in a controlled, protected environment that can be isolated from the rest of the ship in an emergency situation. In addition, this section of the lab is fitted with its own hologrid, which allows for holographic replicas of artifacts, equipment, or other research projects to be generated for analysis by the Engineering team. This allows personnel the opportunity to explore solutions in a controlled environment, limiting the potential danger to the ship and the crew.

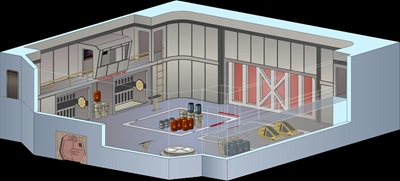

Fabrication/Repair Bay

Located throughout the Engineering spaces of the Starship Enterprise, the combination Fabrication/Repair Bays are large facilities that are focused on the repair and maintenance of the ship and equipment.

Located throughout the Engineering spaces of the Starship Enterprise, the combination Fabrication/Repair Bays are large facilities that are focused on the repair and maintenance of the ship and equipment.Featuring multiple configurations aboard the Enterprise, the default style for the Fabrication/Repair Bay has been designed to streamline repair operations. Consisting of multiple levels, the majority of space within the bay provides space to complete repairs to equipment and other materials. A control booth built into the upper level provides operational control over the functions of the Fabrication/Repair Bay to personnel assigned there. Large-scale Industrial Replicators, designed for construction purposes, are often built into the Fabrication/Repair Bay to aid in assignments.

Fabrication/Repair Bays aboard the Enterprise support the vessel's operations, which often includes the need to access the exterior of the craft. Many bays include an exterior door or are supplemented by Cargo Transporters - larger scale transporters optimized for the transport of inanimate objects - to transport materials to and from the vessel. A Workbee, a maintenance craft equipped with a variety of tools, can also be parked in the Fabrication/Repair Bay when unneeded.

Jefferies Tube Network

Named in honor of Starfleet Captain W. M. Jefferies, the Jefferies Tube Network was used by the crew of the U.S.S. Enterprise to access ship's systems. Also known as an Access Tube or Service Crawlway, in an emergency the tubes could be used for moving around the ship if Turbolifts were not functional.

Named in honor of Starfleet Captain W. M. Jefferies, the Jefferies Tube Network was used by the crew of the U.S.S. Enterprise to access ship's systems. Also known as an Access Tube or Service Crawlway, in an emergency the tubes could be used for moving around the ship if Turbolifts were not functional. Entry to the Jefferies Tube Network was normally provided through the Junction Service Room, which were connection points that linked the tubes together; however, some Jefferies Tubes were directly accessible through hatchways located in corridors or some rooms. Junction Service Rooms frequently had exposed conduits on their walls, sometimes with panels to access to various power conduits or relays available.

Vertical Jeffries Tubes allowed manual access to decks both above and below, which were labeled and included directional information. Each of the vertical tubes were equipped with a single one-way ladder for crewmen to climb or descend. Dim lights were located behind the main ladder and other lights were found on every deck.

Traditionally entered headfirst, the horizontal Jeffries Tubes allowed manual access to various vital parts of a ship or station. Crewmen usually had to crawl while traveling in them due to the cramped size and dim lights were located near the floor and on each side of the tube for illumination. Removable panels inside the tubes provided access to important system conduits and engineering controls.

Enterprise has also been outfitted with diagonal Jefferies Tubes running through the ship's neck and the nacelle pylons that connected to system controls, relays, various conduits, and vital engineering circuits. At the entrance of each tube were two red bars so a crewman could pull themselves inside and stairs for crewmen to use to propel themselves through the tube. A soft, yet strong light was always emitted from the top and filled the entire tube.

Service Corridor

Located on the maintenance levels of the Saucer and Engineering Hulls and within the Warp Drive Nacelles, Service Corridors on the Century Class are passageways that allow Engineering Teams access to shipboard equipment and systems. Similar to the Jefferies Tube Network, Service Corridors served many different functions and purposes aboard the spacecraft and were vital to its survival.

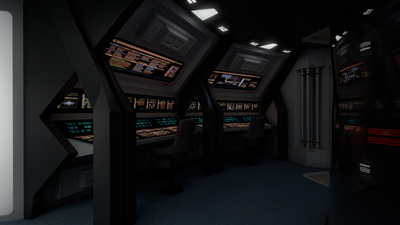

Located on the maintenance levels of the Saucer and Engineering Hulls and within the Warp Drive Nacelles, Service Corridors on the Century Class are passageways that allow Engineering Teams access to shipboard equipment and systems. Similar to the Jefferies Tube Network, Service Corridors served many different functions and purposes aboard the spacecraft and were vital to its survival.Dominating the maintenance areas, Service Corridors were smaller than the traditional corridors found on the crew levels and allowed less room for crewmembers to pass one another. Featuring a rounded layout, the Service Corridor was well lit with large lighting units installed in the ceiling of the unit. Unlike the corridors on the crew levels, equipment and pipes are exposed within the Service Corridors and are not hidden behind panels like in their counterparts and, in some places, may obstruct the walkway creating a tripping hazard. Personnel using these corridors often must exercise caution or they may potentially injure themselves due to the exposed equipment. Direct access to the Jefferies Tube Network is available at multiple locations within the Service Corridors, including exposed ladders that allow access to the upper and lower decks.

Operations Support

Communications Relay Laboratory

By transmission of a subspace radio signal, which traveled through subspace rather than normal space, subspace communication permitted the sending of data and messages across interstellar distances faster than the speed of light. The Communications Relay Laboratory aboard the Starship Enterprise was used to oversee the Communications Systems aboard the vessel and, due to the unique mission parameters of the Enterprise, monitors equipment designed to receive communications signals and re-transmit them to other links in the larger communications network.

By transmission of a subspace radio signal, which traveled through subspace rather than normal space, subspace communication permitted the sending of data and messages across interstellar distances faster than the speed of light. The Communications Relay Laboratory aboard the Starship Enterprise was used to oversee the Communications Systems aboard the vessel and, due to the unique mission parameters of the Enterprise, monitors equipment designed to receive communications signals and re-transmit them to other links in the larger communications network. A two-level compound, primary entry to the Laboratory is through an entry on the lower level of the room. A series of workstations allow for the monitoring and coordination of transmissions, allowing for the easy distribution of messages across long distances. A collaborative work area on the uppermost level includes access sophisticated computer analysis software that can be used to analyze messages that are flagged for further investigation. A large viewscreen monitors the status of the Enterprise's communications system and its ties to the Subspace Communications Network.

Overseen by a Communications Officer, often the Communications Relay Laboratory is utilized by representatives of Starfleet Intelligence and Starfleet Strategic Operations. Due to the sensitive nature of the work conducted in the Communications Relay Lab, access is heavily restricted.

Computer Core (Isolinear)

Located in both the Primary and Stardrive Sections, the Enterprise currently employs two Isolinear based Computer Cores for use as a backup to the vessel's primary computer systems should they become inoperable.

Located in both the Primary and Stardrive Sections, the Enterprise currently employs two Isolinear based Computer Cores for use as a backup to the vessel's primary computer systems should they become inoperable. Consisting of a single unit, the Isolinear Computer Core is based upon tried-and-true Isolinear Optical Chip technology that has been in use since the 24th Century and offers redundancy should the primary computer systems fail. Consisting of thousands of Isolinear Optical Chips, the backup processor is two decks tall and incorporates multiple processor hubs located within the core itself. In the event of primary system failure, the Isolinear Core will assume full control, albeit with limited functions, within .00047 seconds to provide an almost seamless transition via the Optical Data Network (ODN).

Access to the Computer Core is highly restricted with only authorized personnel permitted to visit the Core itself.

Computer Core (Positronic)

Among the most powerful computers ever created, the Computer Cores aboard the Starship Enterprise maintain the starship's central computer. Housing the primary processing equipment, including the computer core processors, the Enterprise currently supports four computer cores that communicate with each other and ship's systems via the Optical Data Network (ODN).

Among the most powerful computers ever created, the Computer Cores aboard the Starship Enterprise maintain the starship's central computer. Housing the primary processing equipment, including the computer core processors, the Enterprise currently supports four computer cores that communicate with each other and ship's systems via the Optical Data Network (ODN).Access to the Computer Core was provided by the Computer Access Room, which provides direct access to the multiple processor hubs and the Positronic Chips inside. Based upon the works of Doctors Noonien Soong, Bruce Maddox, and Agnes Jurati, the Positronic Cores aboard the Enterprise create an artificial neural network that is designed to imitate the humanoid brain. The computational systems are backed up by traditional Isolinear Computer Processing Systems, managed by Isolinear Optical Chips.

Access to the Computer Core is highly restricted with only authorized personnel permitted to visit the Core itself.

Environmental Control Room

The Environmental Control Room of the Starship Enterprise regulates atmospheric conditions, including the concentration of varying gases, lighting, temperature, humidity, and gravity.

The Environmental Control Room of the Starship Enterprise regulates atmospheric conditions, including the concentration of varying gases, lighting, temperature, humidity, and gravity. Located centrally, a large horseshoe shaped workstation dominates the Environmental Control Room and provides priority control over all shipboard life-support systems. While seating is provided for a single operator, the workstation is large enough to allow multiple personnel to work from this location comfortably. Four workstations are built into the aft wall of Environmental Control and provide oversight of a variety of environmental functions aboard the Enterprise. Following a standard Starfleet interface configuration, the consoles are divided with two terminals located on the port and starboard sides of the control room. These stations are separated by a recessed, locked entryway.

Both the forward and aft bulkheads of the Environmental Control Room feature large display terminals. Similar in design to the viewscreen on a starship's Bridge, the forward display features a schematic overview of the Enterprise's Life-Support System and can be used to pinpoint any environmental issue quickly and efficiently. The aft bulkhead features a replica of the Master Situation Monitor Diagram.

Navigational Control Room

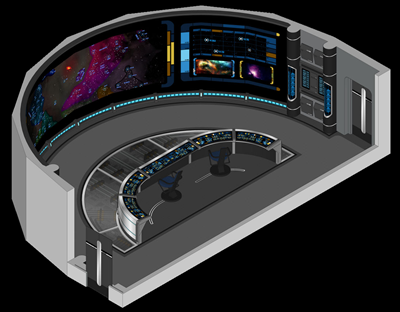

The Navigational Control Room was a section aboard the Federation Century Class starship, like the U.S.S. Enterprise.

The Navigational Control Room was a section aboard the Federation Century Class starship, like the U.S.S. Enterprise.From this location all navigation operations aboard the Enterprise and helps to monitor and project a vessel's course and velocity. The Navigational Control Room is a large room that is dominated by a large, wraparound, holographic wall screen that is designed to display the stellar region from which the vessel is operating. A large, horseshoe shaped control panel was located in the center of the room to manipulate the screen. The console also included priority access to the Enterprise's sensors, allowing for the determination of the position, speed, and trajectory of other objects and ships.

Manned at all times, the Navigational Control Room is commonly a supplement to the Flight Control consoles located elsewhere on the ship. Nonetheless, in a true emergency, the Navigational Control Room can override commands issued by the Bridge and can be used to pilot the vessel if all other options are unavailable.

Plasma Relay Room

Located on the lowest levels of the Starship Enterprise, the Plasma Relay Room was there area where the Electro Plasma from the matter/antimatter reaction of the Warp Core could be routed to different areas and systems of the vessel to increase or decrease power to these areas and systems as necessary.

Located on the lowest levels of the Starship Enterprise, the Plasma Relay Room was there area where the Electro Plasma from the matter/antimatter reaction of the Warp Core could be routed to different areas and systems of the vessel to increase or decrease power to these areas and systems as necessary. Used to control power transfers, the Plasma Relay Room was a small area with workspace for two crewmembers and a supervisor. Due to the limited space, terminals were wall mounted, but featured comfortable seating for personnel assigned as they completed their duties. The supervisor was assigned to a secondary console, located in a small alcove, that separated them from the rest of the team.

Aboard the Enterprise, power transfer requisitions were provided in a manner of ways. Normally, the Main Computer could be used to automate requests; however, due to the nature of the Enterprise's mission, staff were required to oversee and manage this automation. When processing manual requests personnel could submit power transfer requests via computer, or by PADD, with personnel then making the necessary transfers as per the requisition request.

Sensor Maintenance

The Sensor Maintenance Room was used to conduct routine maintenance on the sensor assemblies aboard Century Class Starships like the U.S.S. Enterprise-H.

The Sensor Maintenance Room was used to conduct routine maintenance on the sensor assemblies aboard Century Class Starships like the U.S.S. Enterprise-H.Located near the Primary and Secondary Deflector Dishes aboard the Enterprise, Sensor Maintenance is a spacious room used to monitor the status of the Enterprise's sensors. With a single entryway, most of the Maintenance Room is empty and unused with only a single display table having been installed inside the complex. Capable of seating two personnel on either side of the wall mounted table, the workstation runs continual diagnostics of the shipboard sensor systems and relays the data as appropriate. A large supplemental display monitor mounted on a nearby bulkhead provides a clear overview of the sensor arrays for personnel.

Despite the importance of the sensor arrays, these consoles are not under continual use and many of their operations are automated.

Disclaimer

Categories: No categories found